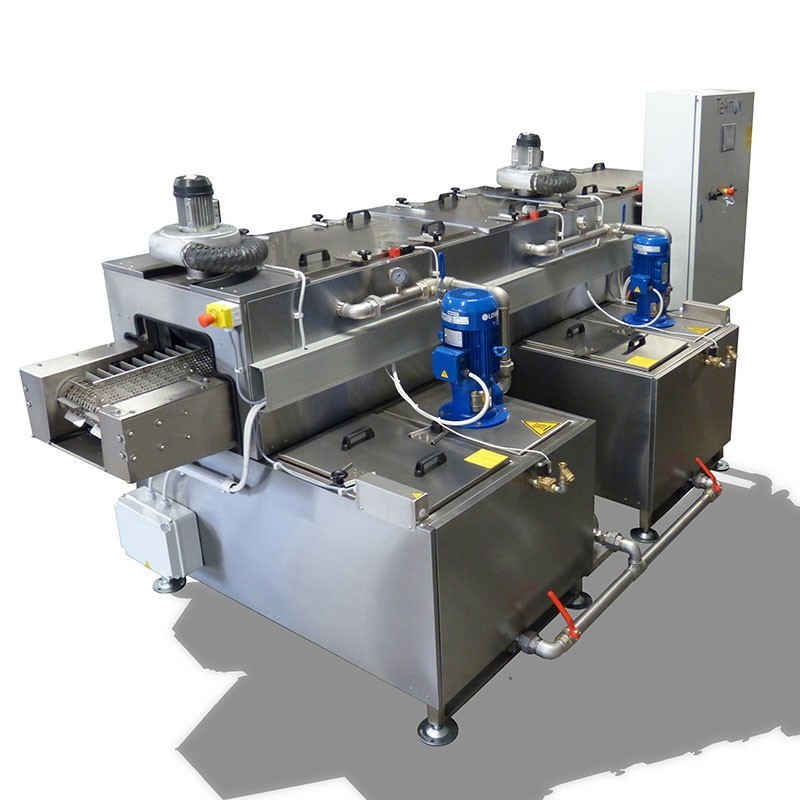

TUNNEL

Brand: Teknox

MULTISTAGE METAL CLEANING TUNNEL FOR COMPLEX AND SERIES PRODUCED MECHANICAL COMPONENTS

The machine consists of several treatment chambers for washing, rinsing, blowing and drying.

They can be single or multi-stage with final drying according to needs.

All operations are performed automatically on the parts as they move along the conveyor belt.

Linear and oval conveyor tunnels

For the treatment of various shapes and sizes with mixed positioning

Linear and oval step-by-step pallet conveyor tunnels

For the customized treatment of technologically complex parts

Pipe tunnels

For the internal and external treatment of profiles of various shapes and sizes

Characteristics

- Reduction of operating and manufacturing costs due to the possibility of incorporating these machines within automatic production areas.

- Reduction of costs through the use of biodegradable environmental friendly chemical detergents.

- High degree of washing cycle automation.

- Optimisation of treatment parameters without the need for constant monitoring by specialised operators.

- The opportunity to treat “technologically complex” components characterised by high production quantities and high final quality requirements.

- The opportunity to increase productivity and improve the efficiency of each production line.

Machineparts

- Electric timed steam extraction

- Feeding via gear motor (inverter-controlled adjustable speed)

- Safety barriers with photocells (in case of manual unloading)

- Total insulation in Stainless steel to reduce costs

- Siemens electric components

- Tank liquid maximum level control and solenoid valve for automatic water intake

- Minimum level control

- Colour 7'' touchscreen display for settings and programs.

- Electric pump in stainless steel with special gaskets

- Box filter with 6 cap filters in Stainless steel AISI 304 for pre-filtering the liquid returning to the tank

- Filter in stainless steel AISI 304 on the pump suction

- IP 65 electric system with PLC touchscreen (DGT V4)

- Weekly programming for the activation of heating and oil separator (if installed)

- Liquid heating with electric resistor in stainless steel

- Structure and plates in STAINLESS steel AISI 304

- Stainless steel AISI 304 washing pipes with laser perforated nozzles